About 100 million people worldwide are exposed to toxic concentrations of naturally occurring arsenic in groundwater supplies, the vast majority living in rural Bangladesh and India (West Bengal, Bihar). Other arsenic-affected areas are found in Vietnam, Thailand, Argentina, Chile, Mexico, China and the United States. The slow accumulation of arsenic in the body causes skin lesions, gangrene, multiple types of cancer, cardiovascular diseases, reduced IQ in children, neuropathy and premature death.

Bengal Basin:

Over 60 million people in Bangladesh and West Bengal (India) drink groundwater contaminated with naturally occurring arsenic. Although the WHO’s recommended maximum limit for arsenic in drinking water is 10 parts per billion (ppb), the arsenic levels can exceed 1000 ppb. Forty thousand people in Bangladesh are already showing signs of arsenic poisoning, in what is rightly called the largest case of mass poisoning in history. A recent 10-year long cohort study published in The Lancet showed that 1 in 5 of all adult deaths in Bangladesh are now due to arsenic.

ECAR from Kindea Labs on Vimeo.

Although there are numerous proposed solutions to this devastating problem, many of them are expensive and/or ineffective at decreasing arsenic in drinking water to acceptable levels. Scientists at Lawrence Berkeley National Labs have developed two methods to affordably and effectively remove arsenic from drinking water. The first method is called Arsenic Removal Using Bottom Ash (ARUBA). Bottom ash, a widely available waste material from coal-fired power plants, is coated with iron rust, which binds to arsenic. The arsenic can then be removed from the water through settling and/or filtration. The second method is called ElectroChemical Arsenic Remediation (ECAR). This method uses a small amount of electricity to create rust in contaminated water. The rust binds to arsenic, which can then be removed from the water through settling and/or filtration.

Susan Addy from Geologie on Vimeo.

Our goal is to design a water treatment system that utilizes LBNL technology to effectively remove arsenic from drinking water within a sustainable business model. Therefore alongside the scientific and engineering development, the team is developing a business model for system implementation. This solution will take into account economic costs/benefits, social acceptability, affordability, and sustainability.

This project is funded by the National Collegiate Inventors & Innovators Alliance, the UC Berkeley Blum Center for Developing Economies, the Haas School of Business Sustainable Products & Solutions (SPS) Program, the UC Berkeley Bears Breaking Boundaries Contest, the Marin San Francisco Jewish Teen Foundation and the EPA P3: People, Prosperity, and the Planet Program.

California:

Thousands of people in California rely on arsenic contaminated groundwater as their primary source for drinking. Limited USGS measurements show that 25% of California public groundwater supply sources exceed the state and federal standard of 10 parts per billion (ppb) of arsenic. This data set is the most comprehensive available, but it excludes over 1.6 million Californians who live in rural areas and rely primarily on groundwater accessed through unregulated private wells.

Rural communities in California are often too poor to afford commonly available arsenic remediation techniques, and most techniques are only cost effective on larger scales (e.g. city water supply systems). As a result, many California residents drink water with dangerous levels of arsenic every day. The burden of arsenic disproportionately falls on minorities and residents of lower socioeconomic status (SES). A recent study of community water systems in the San Joaquin Valley showed that minorities and residents of low SES have higher levels of arsenic in their drinking water and higher levels of non-compliance with drinking water standards.

The first full-scale ECAR pilot plant at Dhapdhapi High School is a 2-hour drive from Kolkata in the South 24 Paraganas District of India. Photos from 2015-2016 show plant machinery, and students, teachers, school and plant staff, and researchers from U.C. Berkeley and Jadavpur University, and also some visitors and children from the nearby community.

Electro-Chemical Arsenic Remediation (ECAR)

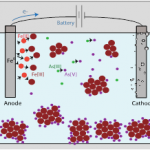

The arsenic removal mechanism in ECAR. Iron (Fe) from the anode dissolves into solution, forming rust. The rust forms complexes with arsenic in solution through adsorption to the rust surface, or precipitation into a new iron-arsenic solid. The arsenic-laden rust complexes are then filtered or settled out of the water.

In ElectroChemical Arsenic Remediation (ECAR), electricity is used to continuously dissolve an iron electrode, forming a type of rust in the water. Arsenic in the water binds to the rust particles, which can then be removed. The rust particles are created electrochemically at the time of use, eliminating the need for a costly supply chain. In addition, electrochemical processes resulting from the use of electricity greatly enhance the arsenic removal capacity (i.e. arsenic removed per unit iron input) relative to the common chemical methods of arsenic removal.

The only inputs required for ECAR treatment are ordinary mild steel plate electrodes and low voltage (< 3 V) electricity. During the ECAR process, trivalent arsenite (As[III]) is oxidized to pentavalent arsenate (As[V]). This is a key reaction, as As[III] does not adsorb as strongly as As[V] to mineral surfaces in natural waters, making it difficult to remove without pre-oxidation to As[V]. Both forms of arsenic are present in appreciable quantities in contaminated groundwater.

ECAR has many advantages over other low-cost arsenic removal methods such as chemical co-precipitation with ferric salts and filtration through activated alumina or granular iron-based adsorbent media. These include:

- Higher adsorption capacity due to the much larger surface area of newly precipitated nano-scale particles

- Ability to oxidize and effectively remove As[III]

- No need to backwash media, (since media are removed by precipitation)

- No need for media regeneration, avoiding the need to handle strong acids or alkalies in the field

- Low maintenance needs (electrodes can be cleaned by automatically reversing the current direction during operation)

- Strong pH buffering ability (no need for pH adjustment)

- No need to import, manufacture, deliver, or handle media or chemical additives

- Very low production of waste sludge

- Amenability to automation

ECAR operates at low voltages (< 3V in real groundwater with steel plates spaced 2 cm apart), easing electrical safety issues. Power can be supplied using grid, battery, or solar photovoltaic sources. The semi-batch process allows for electricity interruptions, and the equipment can be made robust against voltage surges, sags, and spikes. Arsenic-remediated water can be pumped and stored into an elevated delivery tank, preventing water supply disruptions during electricity outages.

Video presenting ECAR and our vision for implementing it. Made by Caroline Delaire in January 2013.

Watch our 2016 video on ECAR and see Overview of the Arsenic Problem for more information.

Active Research Areas

Publications

Outreach Pamphlets and Materials

ECAR FAQs

Air Cathode Assisted Iron Electrocoagulation (ACAIE)

To solve the arsenic problem in California, a low-cost, high-throughput, and robust arsenic removal technology is needed. The Gadgil group has expanded ECAR into a new generation of arsenic treatment technology, called Air-Cathode Assisted Iron Electrocoagulation (ACAIE). ACAIE is a continuous, or flow-through, process (water goes in one side and out the other continuously), unlike the earlier batch process of ECAR. Like ECAR, ACAIE relies on a power supply in order to apply a current to an iron (Fe) sheet serving as the anode. The iron sheet then dissolves into the bulk water as charged ions, which precipitate out as a special kind of rust in order to capture the arsenic. ACAIE breaks new ground by using a carbon-based air diffusion material that generates hydrogen peroxide. This hydrogen peroxide is a powerful oxidant that speeds up chemical reactions in ACAIE, specifically the formation of iron particles and the transformation of arsenite to arsenate, which makes it easier to remove total arsenic in a short treatment time.

ACAIE has progressed from a 500-mL batch reactor to a 60 liter per hour continuous flow system, which is effective in reducing high levels of arsenic from real California groundwater to much below the EPA maximum contaminant level of 10 ppb.

Publications

- Bandaru, Siva RS, Case M. van Genuchten, Arkadeep Kumar, Sara Glade, Dana Hernandez, Mohit Nahata, and Ashok Gadgil. “Rapid and Efficient Arsenic Removal by Iron Electrocoagulation Enabled with in Situ Generation of Hydrogen Peroxide.” Environmental Science & Technology 54, no. 10 (2020): 6094-6103.

- Gadgil, Ashok, Dana Hernandez. “Addressing arsenic problems in rural CA”. The Daily Californian. October 22, 2020. https://www.dailycal.org/2020/03/20/arsenic/

Presentations

- Hernandez, Dana. “Developing an effective electrochemical arsenic remediation technology for adoption in the Central Valley of California”. Environmental Engineering Seminar Series, Lightning Talk. UC Berkeley. November 6, 2020.

- Gadgil, Ashok. “Affordably Removing Arsenic from Drinking Water: Science, Engineering, and Implementation”. National Environmental Engineering Research Institute. Webinar Lecture Series on Advanced Water and Wastewater Treatment. July 1, 2020. Link: https://www.youtube.com/watch?v=aDOtn5-MOoY. Talk begins at about 5 minutes and ends at about 40 minutes.

- Hernandez, Dana, Ashok Gadgil. “Novel technology to solve the rural crisis of arsenic in drinking water”. UC Global Health Day. The UC Global Health Institute. May 2, 2020.

- Bandaru, Siva Rama Satyam, Case M Van Genuchten, Arkadeep Kumar, Dana Hernandez, Mohit Nahata, Sara Glade, Ashok Gadgil. “An extremely rapid and efficient engineered system to remove arsenic in the groundwater used for drinking”. AGU Fall Meeting. December 10, 2019.

- Hernandez, Dana, Siva Bandaru, Ashok Gadgil. “Air cathode assisted iron electrocoagulation: An effective and high-throughput arsenic remediation technology for contaminated groundwater in rural California”. Abstracts of Papers of the American Chemical Society 257. April 3, 2019.

- Kumar, Arkadeep, Siva Bandaru, Case van Genuchten, Mohit Nahata, Dana Hernandez, Ashok Gadgil. “Structure of iron oxides generated in air-cathode assisted iron-electrocoagulation for water treatment”. Abstracts of Papers of the American Chemical Society 258. April 3, 2019.

- Bandaru, Siva Rama Satyam, James Barazesh, Carsten Prasse, Case Van Genuchten, Ashok Gadgil. “Air cathode assisted iron-electrocoagulation for treating wastewater for emerging contaminants”. Abstracts of Papers of the American Chemical Society 257. March 31, 2019.

- Kumar, Arkadeep, Siva RS Bandaru, Mohit Nahata, Nate Hohman, Ashok Gadgil. “Fouling Characterization and Effectiveness of Countermeasures in Air-cathode Assisted Iron-Electrocoagulation (ACAIE)”. Abstracts of Papers of the American Chemical Society 257. March 31, 2019.

- Bandaru, Siva Rama Satyam, James Barazesh, Carsten Prasse, Ashok Gadgil“Air cathode iron-electrocoagulation for removing wastewater-derived contaminants of concern”. Abstracts of Papers of the American Chemical Society 256. August 19, 2018.

We propose that either ARUBA or ECAR should be used in community-based treatment facilities. A locally hired technician maintains the facility, while a local social worker educates villagers on the importance of clean water. These facilities will be profitable and sustainable due to low overhead costs, and the low cost of both ARUBA and ECAR.

ECAR and ARUBA are available for licensing from the Lawrence Berkeley National Laboratory Technology Transfer Division. Contact ttd@lbl.gov for more information on licensing ECAR.

Global Change Programme, Jadavpur University, Kolkata

Principal Investigator Ashok Gadgil in an interview about using science help the world’s poor

Berkeley Electrocoagulation Arsenic Removal (BEAR) student group Blog from Cambodia Fieldwork

More information about the Arsenic Problem

Detailed 10-year study about Arsenic exposure from drinking water in Bangladesh

World Health Organization on Arsenic

Chronic Arsenic Poisoning: History, Study and Remediation (Harvard University)

Other Groups doing Arsenic Research

Lex van Geen (Columbia University)

Supporters and Sponsors

Lawrence Berkeley National Laboratory

Energy and Resource Group, UC Berkeley

NCIIA: National Collegiate Inventors and Innovators Alliance

Blum Center for Developing Economies

UC Berkeley Bears Breaking Boundaries Context

Haas School of Business Sustainable Products & Solutions (SPS) Program